February 9, 2026

How to Solvent Weld Uponor ChlorFIT® Schedule 80 Corzan® CPVC

By Alex Gross

Uponor ChlorFIT® Schedule 80 Corzan® CPVC meets the demands of commercial plumbing environments with high-pressure tolerance, long-lasting reliability, and tested chemical resistance, providing a strong foundation for potable water distribution. This system uses solvent welding, a specialized joining process that permanently fuses the pipe and fitting.

Learn how to make a reliable solvent weld to capitalize on the engineered strength of Schedule 80 Corzan CPVC.

Internal Deburring

Deburr the inside edge of the pipe.

External Pipe Chamfering

Chamfer the outside edge of the pipe.

Surface Preparation and Cleaning

Clean the pipe and fitting with an approved cleaner for Schedule 80 CPVC.

Precision Depth Marking

Measure the fitting hub depth, then mark that depth on the pipe.

Pro tip: Mark the pipe a second time, two inches from the first mark, to verify full insertion after you complete the weld.

Interference Fit Verification

Dry fit the fitting hub.

Pro tip: Insert the pipe between one-third and two-thirds of the way into the fitting.

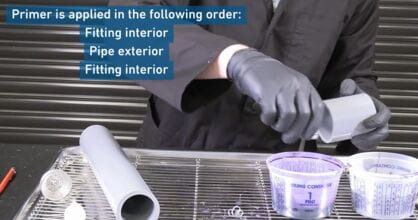

Strategic Primer Application

Apply primer to the fitting interior, then to the pipe exterior. Finish with a final coat on the fitting interior. Follow this sequence to properly bond the materials

Consistent Cement Coating

Immediately after applying primer, apply cement to the pipe exterior, then to the fitting interior. Finish with a final coat on the pipe exterior.

Pro tip: Apply a thin coat of cement to avoid puddling and protect the connection's integrity.

Rapid Assembly and Set

Assemble the parts quickly while the cement is fluid. Ensure the pipe bottoms out in the fitting; hold it firmly for several seconds to prevent pushback.

Final Joint Cleanup

Wipe off any excess cement after securing the connection.

A successful solvent weld requires precise preparation and assembly. To ensure a reliable connection, be sure to prioritize safety protocols, adhere to manufacturer cure schedules, and account for environmental conditions during installation.

Prioritize Safety and Protection

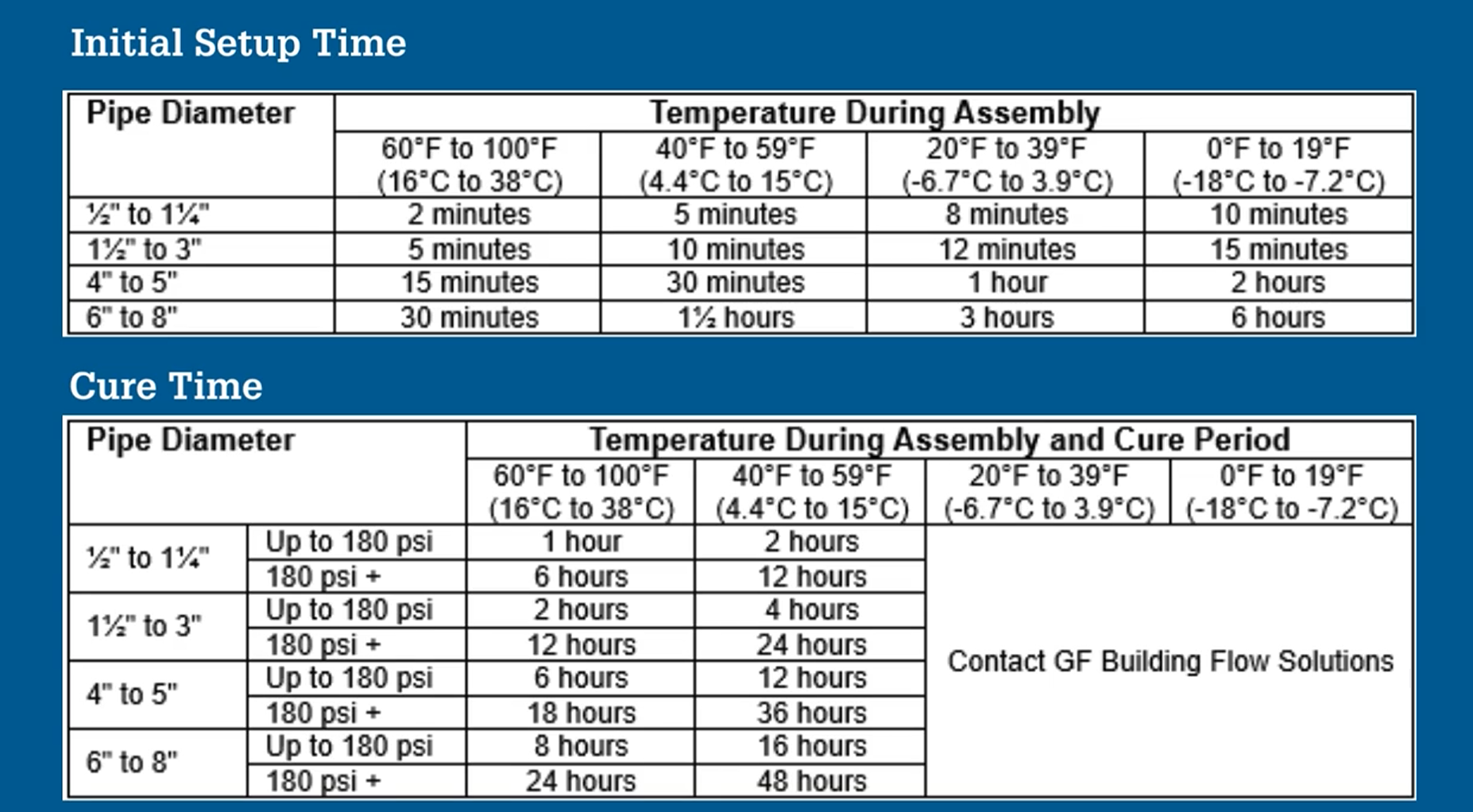

Use the following chart as a guide for initial setup and cure times when connecting to Uponor ChlorFIT. However, solvent and cement manufacturers determine specific setup and cure times for their products. Refer to their guidelines for the exact times to ensure strong connections.

Beyond setup and cure times, job site temperatures affect how these chemicals react and their ability to form a reliable connection.

Cold Weather Installation Tips

Following this process, adhering to safety protocols, and accounting for environmental factors will promote successful performance of an Uponor ChlorFIT piping system.

See the process in action by watching our video, “How to Solvent Weld Uponor ChlorFIT® Schedule 80 Corzan® CPVC.”

Corzan® is a registered trademark of Lubrizol Advanced Materials, Inc.

Learn how to make a reliable solvent weld to capitalize on the engineered strength of Schedule 80 Corzan CPVC.

Internal Deburring

Deburr the inside edge of the pipe.

External Pipe Chamfering

Chamfer the outside edge of the pipe.

Surface Preparation and Cleaning

Clean the pipe and fitting with an approved cleaner for Schedule 80 CPVC.

Precision Depth Marking

Measure the fitting hub depth, then mark that depth on the pipe.

Pro tip: Mark the pipe a second time, two inches from the first mark, to verify full insertion after you complete the weld.

Interference Fit Verification

Dry fit the fitting hub.

Pro tip: Insert the pipe between one-third and two-thirds of the way into the fitting.

Strategic Primer Application

Apply primer to the fitting interior, then to the pipe exterior. Finish with a final coat on the fitting interior. Follow this sequence to properly bond the materials

Consistent Cement Coating

Immediately after applying primer, apply cement to the pipe exterior, then to the fitting interior. Finish with a final coat on the pipe exterior.

Pro tip: Apply a thin coat of cement to avoid puddling and protect the connection's integrity.

Rapid Assembly and Set

Assemble the parts quickly while the cement is fluid. Ensure the pipe bottoms out in the fitting; hold it firmly for several seconds to prevent pushback.

Final Joint Cleanup

Wipe off any excess cement after securing the connection.

A successful solvent weld requires precise preparation and assembly. To ensure a reliable connection, be sure to prioritize safety protocols, adhere to manufacturer cure schedules, and account for environmental conditions during installation.

Prioritize Safety and Protection

- Wear appropriate Personal Protective Equipment (PPE), including safety glasses with side shields and rubber gloves.

- Avoid eye and skin contact with solvent cement.

- Perform the solvent weld in a well-ventilated area.

Use the following chart as a guide for initial setup and cure times when connecting to Uponor ChlorFIT. However, solvent and cement manufacturers determine specific setup and cure times for their products. Refer to their guidelines for the exact times to ensure strong connections.

Beyond setup and cure times, job site temperatures affect how these chemicals react and their ability to form a reliable connection.

Cold Weather Installation Tips

- Warm the pipe and fitting surfaces to at least -15°F (-26°C) prior to making connections.

- Keep primers/cements in warm areas above 40°F (4°C) prior to use.

- Cold surfaces slow solvent permeation. Use extra effort to work the primer into the pipe and fitting.

- Allow longer cure times before pressure testing.

- Keep pipe/fitting surfaces and primers/cements cooler than 110°F (43°C) before making connections.

- Verify that both surfaces are the same temperature and thoroughly coat them with solvent.

- Solvents permeate hot surfaces more rapidly. Prevent the cement from puddling and clean up any excess.

Following this process, adhering to safety protocols, and accounting for environmental factors will promote successful performance of an Uponor ChlorFIT piping system.

See the process in action by watching our video, “How to Solvent Weld Uponor ChlorFIT® Schedule 80 Corzan® CPVC.”

Corzan® is a registered trademark of Lubrizol Advanced Materials, Inc.