Uponor

The step-by-step guide to Minitec installation; a low-profile system

21 June 2021

The step-by-step guide to Minitec installation; a low-profile system

Underfoot Underfloor heating (UFH) is quickly going from aspirational luxury to a standard must-have, with figures indicating that the market is growing 10% per year. This popularity is being driven by a number of factors, such as an increased awareness around energy efficiency and how UFH provides economic, thermal comfort and space saving benefits.

The step-by-step guide to Minitec installation; a low-profile system

Underfoot Underfloor heating (UFH) is quickly going from aspirational luxury to a standard must-have, with figures indicating that the market is growing 10% per year. This popularity is being driven by a number of factors, such as an increased awareness around energy efficiency and how UFH provides economic, thermal comfort and space saving benefits.

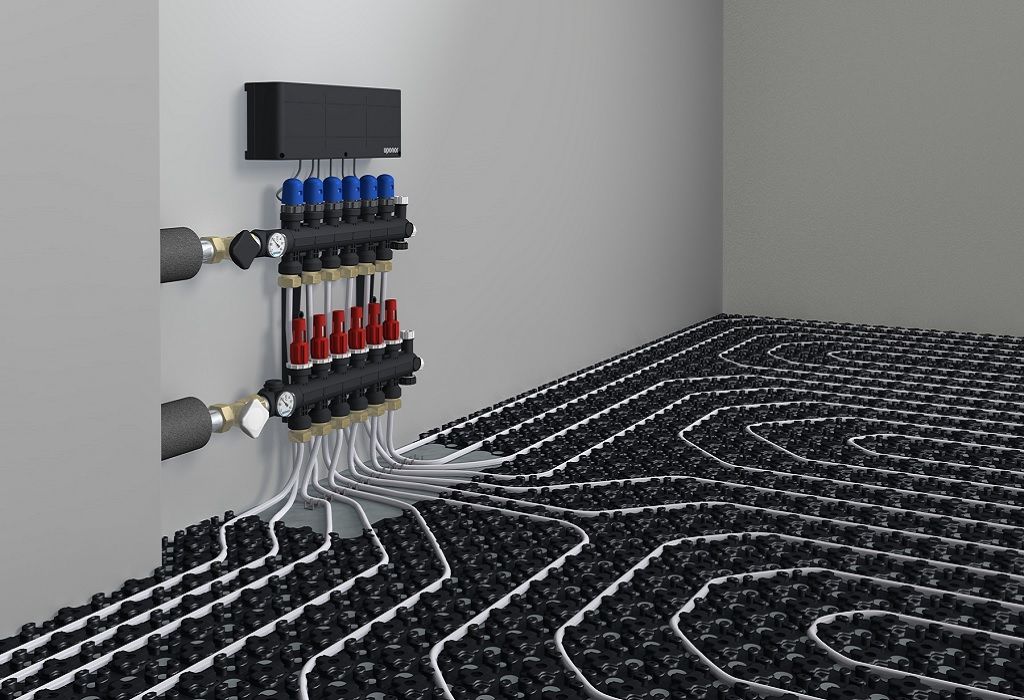

For a long time, this type of heating was the preserve of new builds, with retrofitting seen as too time consuming, expensive and difficult. However, better knowledge and improved technology has led to low-profile systems that are ideal for retrofit projects thanks to the specialist heights and designs that they come in. This type of system can be laid onto solid concrete, timber suspended floors or tiles and allow for numerous floor coverings to be installed on top.

There are several key differences between installing a regular UFH system and a low-profile one. To help illustrate how to install a low-profile system, we’ve compiled a step-by-step guide to applying the ultra-thin, wet-screed based system Minitec.

There are several key differences between installing a regular UFH system and a low-profile one. To help illustrate how to install a low-profile system, we’ve compiled a step-by-step guide to applying the ultra-thin, wet-screed based system Minitec.